High Voltage Connector Overview

High-voltage connectors, inonziwo high-voltage connectors, imhando yemotokari yekubatanidza. Ivo vanowanzo reva zvinobatanidza zvine voltage inoshanda pamusoro pe60V uye inonyanya kuita basa rekufambisa mafungu makuru.

High-voltage connectors inonyanya kushandiswa mu-high-voltage uye high-current circuits yemotokari dzemagetsi. Vanoshanda newaya kutakura simba rebhatiri paki kuburikidza nemaseketi emagetsi akasiyana kune akasiyana siyana ari mumotokari system, senge bhatiri mapaketi, mota controller, uye DCDC converters. high-voltage zvikamu zvakadai sema converter uye majaja.

Parizvino, kune matatu makuru masisitimu epamusoro-voltage majoini, anoti LV yakajairwa plug-in, USCAR yakajairwa plug-in, uye Japanese standard plug-in. Pakati peaya matatu plug-ins, LV parizvino ine yakakura kutenderera mumusika wepamba uye yakanyanya kukwana maitiro maitiro.

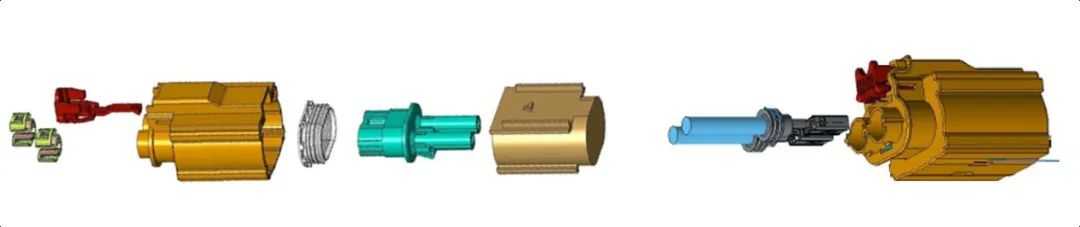

High voltage connector assembly process diagram

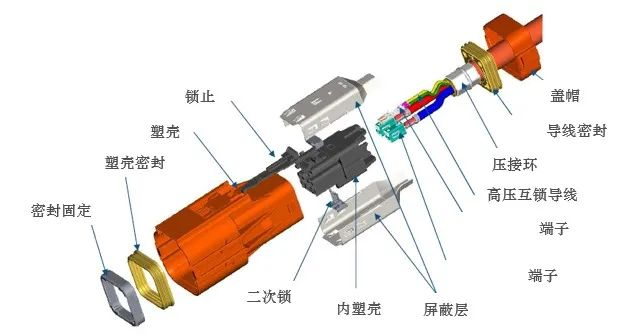

Basic chimiro chepamusoro voltage connector

High-voltage connectors anonyanya kuumbwa mana ekutanga zvimiro, zvinoti contactors, insulators, epurasitiki shells uye accessories.

(1) Mazita: mativi epakati anopedzisa kubatana kwemagetsi, anoti materminal echirume neechikadzi, tsanga, nezvimwewo;

(2) Insulator: inotsigira vanobatika uye inova nechokwadi chekudzivirira pakati pevanobatika, ndiko kuti, mukati mepurasitiki shell;

(3) Plastiki shell: Iyo shell yekubatanidza inovimbisa kurongeka kwechibatanidza uye inodzivirira yose yekubatanidza, kureva, kunze kwepurasitiki shell;

(4) Zvishandiso: zvinosanganisira zvimiro zvekushandisa uye zvishongedzo zvekuisa, zvinoti mapini ekumisa, mapini ekutungamira, mhete dzekubatanidza, zvindori zvekuisa chisimbiso, zvinotenderera zvinotenderedza, zvimiro zvekukiya, nezvimwe.

High voltage connector yakaputika maonero

Classification ye high voltage connectors

High voltage connectors inogona kusiyaniswa nenzira dzinoverengeka. Kunyangwe iyo yekubatanidza ine basa rekudzivirira, nhamba yemapini ekubatanidza, nezvimwe zvese zvinogona kushandiswa kutsanangura iyo yekubatanidza classification.

1.Ingave kana kwete pane nhovo

High-voltage connectors yakakamurwa kuva isina kuvharidzirwa zvibatanidza uye shielded connectors zvichienderana nokuti vane mabasa ekudzivirira.

Zvibatanidza zvisina kuvharidzirwa zvine chimiro chakareruka, hapana chekudzivirira, uye mutengo wakaderera. Inoshandiswa munzvimbo dzisingade dziviriro, dzakadai semidziyo yemagetsi yakavharwa nemakesi esimbi akadai semasekete ekuchaja, zvemukati mebhatiri, uye kutonga mukati.

Mienzaniso yezvibatanidza zvisina shielding layer uye isina high-voltage interlock dhizaini

Shielded connectors ane zvimiro zvakaoma, zvidziviriro zvinodiwa, uye mutengo wakanyanya. Inokodzera nzvimbo dzinodiwa kudzivirira basa, sekunge uko kunze kwemidziyo yemagetsi yakabatana kune yakakwirira-voltage wiring harnesses.

Chibatanidza chine nhoo uye HVIL dhizaini Muenzaniso

2. Nhamba yemapulagi

High-voltage connectors yakakamurwa zvichienderana nehuwandu hwekubatanidza ports (PIN). Parizvino, iyo inonyanya kushandiswa i1P yekubatanidza, 2P yekubatanidza uye 3P yekubatanidza.

Iyo 1P yekubatanidza ine yakapusa chimiro uye yakaderera mutengo. Iyo inosangana nekudzivirira uye kudzivirira mvura zvinodiwa zveakakwira-voltage masisitimu, asi nzira yegungano iri kuomesesa uye rework operability haina kunaka. Kazhinji inoshandiswa mumabhatiri mapaketi uye mota.

2P uye 3P zvibatanidza zvine zvimiro zvakaoma uye zvakati kudhura. Inosangana nekudzivirira uye kudzivirira mvura zvinodiwa zve-high-voltage systems uye ine kuchengetedza kwakanaka. Inowanzo shandiswa kupinza uye kubuda kweDC, senge pa-high-voltage bhatiri packs, controller terminals, charger DC inobuda zviteshi, nezvimwe.

1P/2P/3P high voltage connector muenzaniso

General zvinodiwa kune yakakwirira voltage connectors

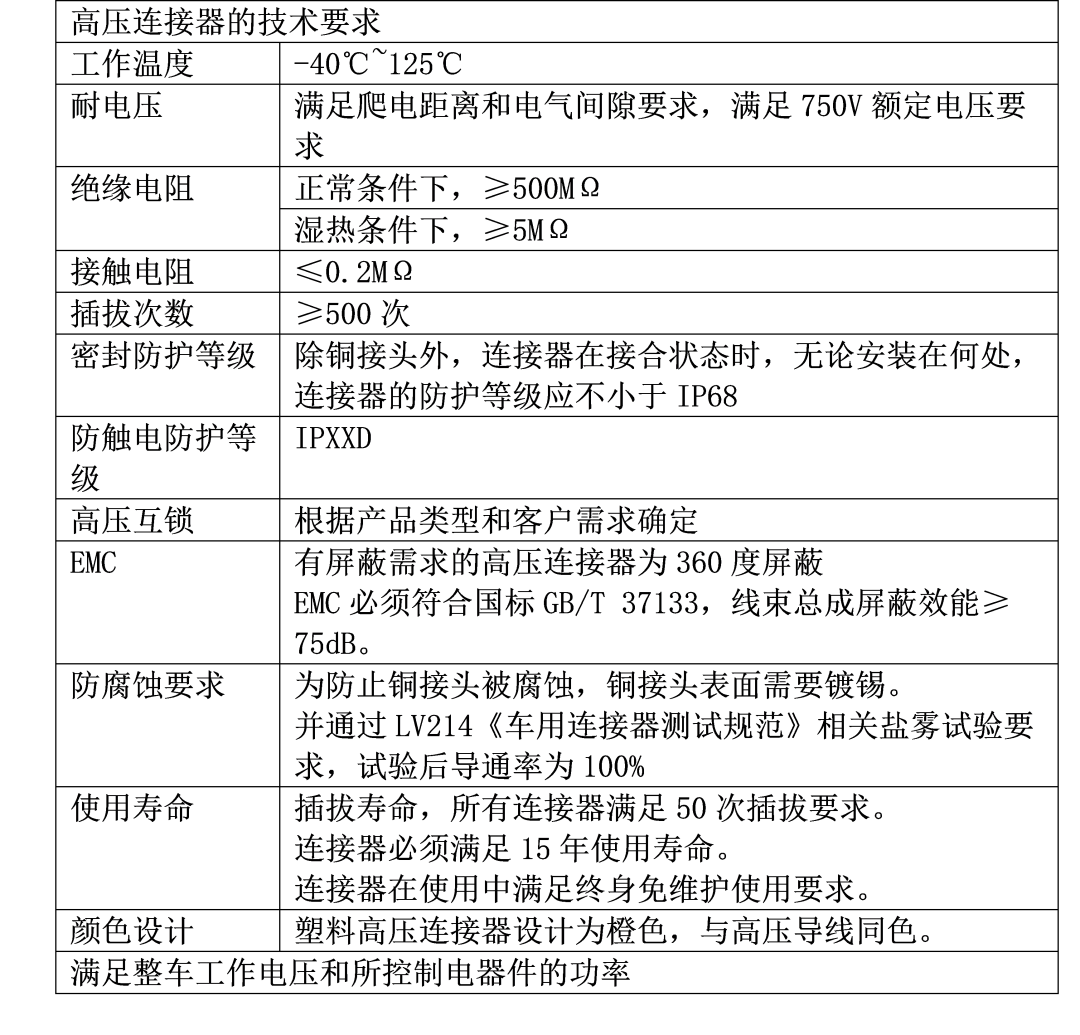

High-voltage connectors inofanira kuenderana nezvinodiwa zvinotsanangurwa neSAE J1742 uye iine zvinotevera tekinoroji zvinodiwa:

Zvido zvehunyanzvi zvinotsanangurwa neSAE J1742

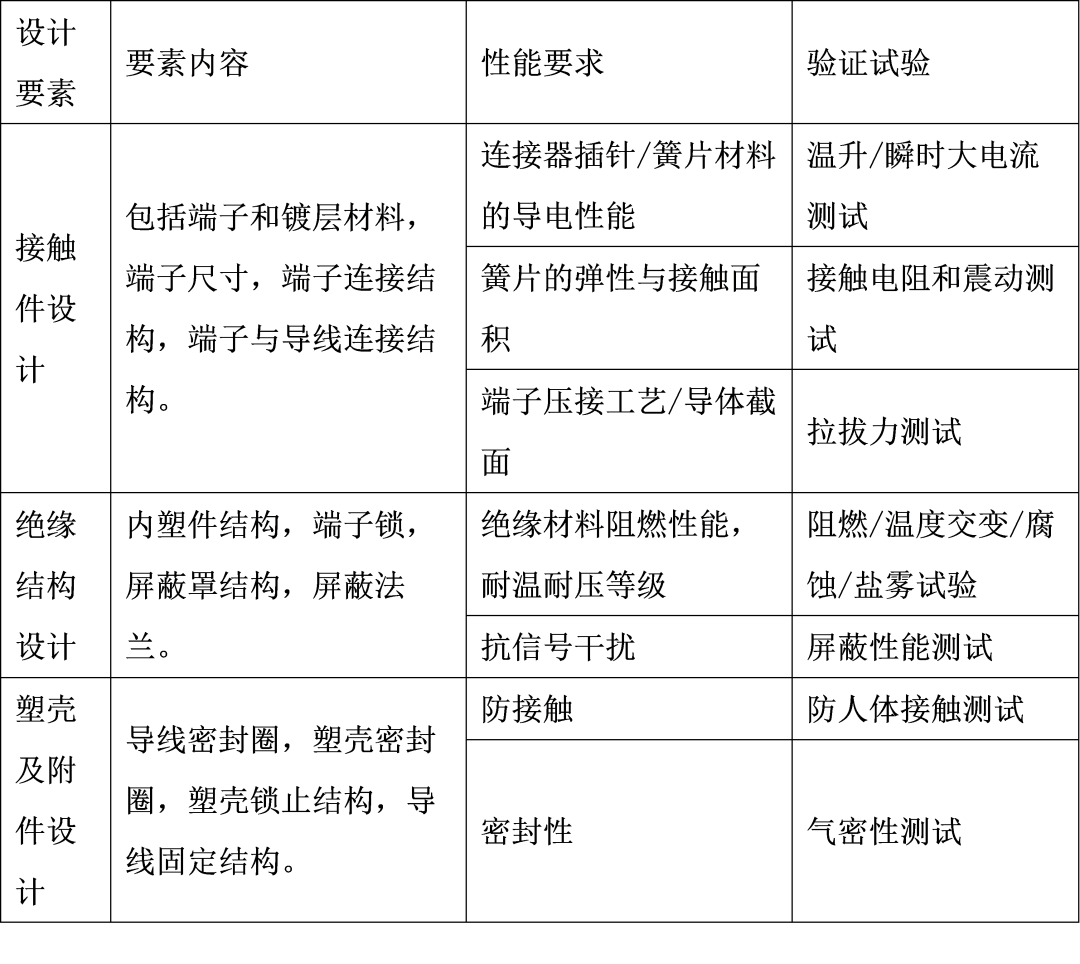

Dhizaini zvinhu zve high voltage connectors

Zvinodiwa zve-high-voltage connectors mu-high-voltage systems zvinosanganisira asi hazvirevi kune: high voltage uye high current performance; kukosha kwekukwanisa kuwana mazinga akakwirira ekudzivirira pasi pemamiriro akasiyana-siyana ekushanda (senge tembiricha yakakwira, vibration, kudhumhana, kusapinda guruva uye kusapinda kwemvura, nezvimwewo); Iva nekuisa; kuve neakanaka electromagnetic shielding performance; mari yacho inofanira kuva yakaderera sezvinobvira uye yakasimba.

Zvinoenderana nehunhu huri pamusoro uye zvinodiwa izvo high-voltage connectors zvinofanirwa kuve nazvo, pakutanga kwekugadzirwa kwe-high-voltage connectors, zvinotevera dhizaini zvinhu zvinofanirwa kutariswa uye zvakanangwa dhizaini uye bvunzo yekuongorora inoitwa.

Rondedzero yekuenzanisa yedhizaini zvinhu, inoenderana mashandiro uye verification bvunzo dzeyakakwira-voltage connectors

Kutadza kuongororwa uye zviyero zvinowirirana zve-high-voltage connectors

Kuti uvandudze kuvimbika kwekubatanidza dhizaini, maitiro ayo ekutadza anofanira kutanga aongororwa kuitira kuti inopindirana yekudzivirira dhizaini basa riitwe.

MaConnectors anowanzo ane matatu makuru ekutadza modes: kusabatana zvakanaka, kusasimba kwekuisa, uye kusununguka kugadzirisa.

(1) Nekutadza kubata, zviratidzi zvakaita senge static yekubata kuramba, yakasimba yekubata kuramba, rimwe gomba rekuparadzanisa simba, mapoinzi ekubatanidza uye vibration kuramba kwezvikamu zvinogona kushandiswa kutonga;

(2) Nekushomeka kwakashata, kudzivirira kwekudzivirira kweiyo insulator, iyo nguva yekushatisa mwero weiyo insulator, saizi zviratidzo zveiyo insulator, mabatiro uye zvimwe zvikamu zvinogona kuwonekwa kutonga;

(3) Nekuvimbika kweiyo yakagadziriswa uye yakavharwa mhando, kushivirira kwegungano, nguva yekutsungirira, kubatanidza pini yekuchengetedza simba, kubatanidza pini yekuisa simba, simba rekuchengetedza pasi pemamiriro ekushushikana kwezvakatipoteredza uye zvimwe zviratidzo zveiyo terminal uye yekubatanidza inogona kuedzwa kutonga.

Mushure mekuongorora maitiro makuru ekutadza uye mafomu ekutadza echibatanidza, matanho anotevera anogona kutorwa kuvandudza kuvimbika kweiyo yekubatanidza dhizaini:

(1) Sarudza chibatanidza chakakodzera.

Kusarudzwa kwezvibatanidza hakufaniri kungofunga nezvemhando uye nhamba yemasekete akabatanidzwa, asiwo kufambisa kuumbwa kwemidziyo. Semuyenzaniso, denderedzwa zvibatanidza hazvinyanyi kukanganiswa nemamiriro ekunze uye michina zvinhu kupfuura rectangular connectors, vane kushoma mechanicha kupfeka, uye akavimbika akabatana kune magumo ewaya, saka denderedzwa zvibatanidza zvinofanirwa kusarudzwa zvakanyanya sezvinobvira.

(2) Kuwanda kwenhamba yevanobatika mukubatanidza, kuderera kwekuvimbika kwehurongwa. Naizvozvo, kana nzvimbo uye uremu zvichibvumira, edza kusarudza chinongedzo chine nhamba diki yevanobatika.

(3) Paunosarudza chibatanidza, mamiriro ekushanda emidziyo anofanira kufungwa.

Izvi zvinodaro nekuti iyo yakazara mitoro ikozvino uye yakanyanya kushanda ikozvino yekubatanidza inowanzogadziriswa zvichienderana nekupisa kunobvumidzwa kana uchishanda pasi pemamiriro ekushisa epamusoro enzvimbo yakapoteredza. Kuti uderedze kupisa kwekushanda kwechibatanidza, mamiriro ekupisa kupisa kwekubatanidza kunofanira kunyatsotariswa. Semuenzaniso, mapikicha ari kure nechepakati pechibatanidza anogona kushandiswa kubatanidza magetsi, izvo zvinonyanya kubatsira pakupisa kupisa.

(4) Isingapindi mvura uye inopesana nekuora.

Kana chinongedzo chichishanda munzvimbo ine gasi rinoparadza uye zvinwiwa, kuitira kudzivirira kuora, kutarisisa kunofanirwa kubhadharwa kune mukana wekuiisa yakatwasuka kubva padivi panguva yekuisa. Kana mamiriro achida kumisikidzwa yakatwasuka, mvura inofanirwa kudzivirirwa kubva mukuyerera ichipinda mukochekera pamwe nemitungamiri. Kazhinji shandisa zvibatanidza zvisingapindi mvura.

Mapoinzi akakosha mukugadzirwa kweakakwira-voltage connector contacts

Tekinoroji yekubatanidza tekinoroji inonyanya kuongorora nzvimbo yekusangana uye simba rekubata, kusanganisira yekubatanidza yekubatanidza pakati pematerminals nemawaya, uye kubatana kwekubatana pakati pematerminals.

Kuvimbika kwevanobatika chinhu chakakosha pakuona kuvimbika kwehurongwa uye zvakare chikamu chakakosha chese yakakwirira-voltage wiring harness assembly.. Nekuda kwekukasharara kwenzvimbo yekushanda kwemamwe materminals, waya uye maconnectors, kuwirirana pakati pematerminals newaya, uye kubatana pakati pematerminals nematerminals kunowanzoitika mukutadza kwakasiyana, sekuora, kuchembera, uye kusunungura nekuda kwekudengenyeka.

Sezvo kutadza kwemagetsi wiring harness kunokonzerwa nekukuvara, kusununguka, kudonha, uye kutadza kweaiti account yeanopfuura 50% yekutadza muhurongwa hwese hwemagetsi, kutarisisa kwakazara kunofanirwa kubhadharwa kune kuvimbika dhizaini yevanobatika mukuvimbika dhizaini yemotokari yakakwira-voltage magetsi system.

1. Kubatana kwekubatana pakati peterminal newaya

Kubatana pakati pematerminals nemawaya kunoreva kubatana pakati pezviviri izvi kuburikidza necrimping process kana ultrasonic welding process. Parizvino, iyo crimping process uye ultrasonic welding process inowanzoshandiswa mune yakakwira-voltage waya harnesses, imwe neimwe iine zvayakanakira nezvayakaipira.

(1) Crimping process

Iyo musimboti weiyo crimping process ndeye kushandisa simba rekunze kungosvina munyama waya conductor muchikamu chakacheneswa cheterminal. Kureba, hupamhi, muchinjika-chikamu nyika uye simba rekudhonza reterminal crimping ndizvo zvemukati zviri mukati meiyo terminal crimping mhando, iyo inotaridza kunaka kwekukoromoka.

Nekudaro, zvinofanirwa kucherechedzwa kuti iyo microstructure yechero yakagadziridzwa yakaomeswa nzvimbo yakasimba inogara yakaoma uye isina kuenzana. Mushure mekunge materminals nemawaya adzimwa, hakusi kubatwa kwese kwese kwese, asi kusangana kwemamwe mapoinzi akapararira pane yekubata kumeso. , iyo chaiyo yekubata kumeso inofanira kunge iri diki pane theoretical yekubata kumeso, icho chiri zvakare chikonzero nei kusangana kwekupokana kwecrimping process kwakakwira.

Mechanical crimping inobatwa zvakanyanya neiyo crimping process, sekumanikidza, crimping urefu, etc. Kudzora kugadzirwa kunoda kuitwa kuburikidza nenzira dzakadai secrimping urefu uye profil analysis/metallographic analysis. Naizvozvo, iyo crimping kuenderana kweiyo crimping process ndeyepakati uye chishandiso chinopfeka ndeye Mhedzisiro yakakura uye kuvimbika kuri pakati.

Iyo crimping process ye mechanical crimping yakakura uye ine dzakasiyana siyana dzekushandisa. Itsika yechinyakare. Vanenge vese vatengesi vakuru vane zvigadzirwa zvewaya vachishandisa maitiro aya.

Terminal uye waya yekubata profiles uchishandisa crimping process

(2) Ultrasonic welding process

Ultrasonic welding inoshandisa yakakwira-frequency vibration waves kuendesa kune pamusoro pezvinhu zviviri zvinosungirirwa. Nekumanikidzika, nzvimbo dzezvinhu zviviri izvi dzinokweshana kuti dziite musanganiswa pakati pema molecular layer.

Ultrasonic welding inoshandisa ultrasonic jenareta kushandura 50/60 Hz yazvino kuita 15, 20, 30 kana 40 KHz simba remagetsi. Iyo yakashandurwa yakakwirira-frequency simba remagetsi rinoshandurwa zvakare kuita mechanical motion of the same frequency kuburikidza ne transducer, uye ipapo mechanical motion inotumirwa kune welding musoro kuburikidza neseti yezvigadziri zvenyanga zvinogona kuchinja amplitude. Musoro wewelding unoendesa iyo yakagamuchirwa vibration simba kujoinhi yeworkpiece kuti isungirwe. Munzvimbo iyi, simba rekuzunguza rinoshandurwa kuita simba rekupisa kuburikidza nekukweshana, kunyungudutsa simbi.

Panyaya yekushanda, iyo ultrasonic welding process ine diki yekubata kuramba uye yakaderera overcurrent kupisa kwenguva yakareba; maererano nekuchengeteka, yakavimbika uye haisi nyore kusunungura uye kuwira pasi pasi pekudengenyeka kwenguva refu; inogona kushandiswa kugadzira pakati pezvinhu zvakasiyana; inobatwa nepamusoro oxidation kana kupfekedza Inotevera; iyo welding mhando inogona kutongwa nekutarisa akakodzera mafungu eiyo crimping process.

Kunyange zvazvo mari yemidziyo ye ultrasonic welding process yakakwira, uye zvikamu zvesimbi zvinosungirirwa hazvigone kuve zvakakora (kazhinji ≤5mm), ultrasonic welding i mechanical process uye hapana ikozvino inoyerera panguva yese welding process, saka hapana Nyaya dzekupisa conduction uye resistivity ndiwo mafambiro emangwana e-high-voltage waya harness welding.

Zviteshi uye maconductor ane ultrasonic welding uye yavo yekubata muchinjiko-zvikamu

Pasinei neiyo crimping process kana ultrasonic welding process, mushure meiyo terminal yakabatana newaya, simba rayo rekudhonza rinofanirwa kusangana nezvinodiwa. Mushure mekunge waya yabatanidzwa kune chinongedzo, simba rekudhonza-kubvisa harifanirwe kunge riri pasi peiyo shoma yekudhonza-off simba.

Nguva yekutumira: Zvita-06-2023